We are only satisfied when you are

Each customer is unique in its requirements and applications. That is why each one is individually looked after by our experienced team according to his or her wishes.

Our service ranges from electronic certificates documenting the quality, processing, treatment and marking of the pipes to suitable transport packaging with labelling according to customer requirements and transport route. The project and package business naturally also includes the supply of piping accessories such as bends, fittings, flanges, gaskets, and "special products".

Material testing – for lasting quality

A boiler tube remains in use for up to 25 years and more. In order to fulfil the principle of a quality product for the customer with certainty, BARTHEL cooperates closely with the materials testing company MT Laboratories GmbH.

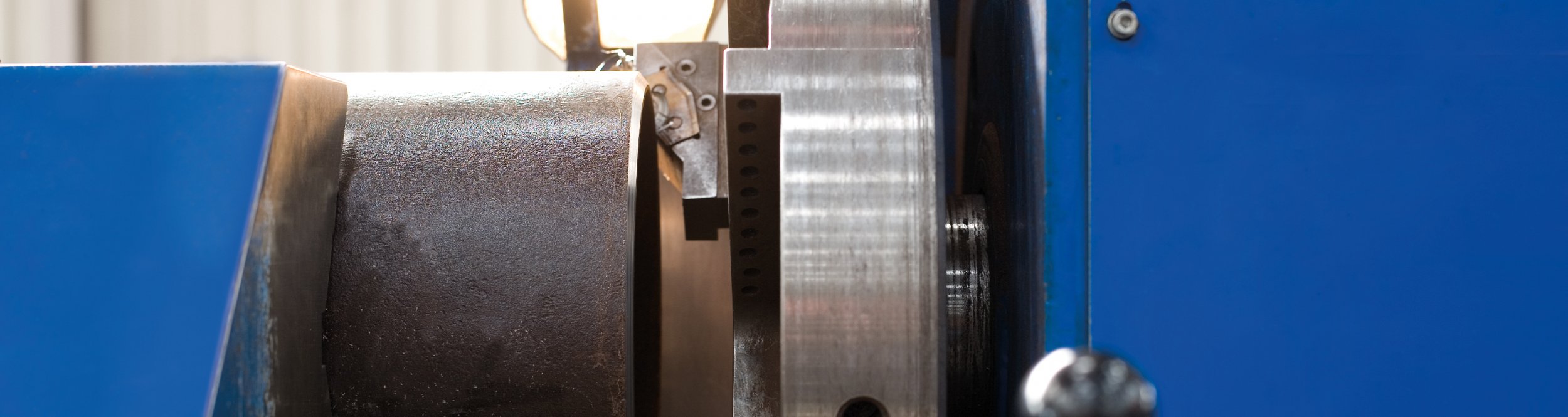

Mechanical processing: Precision in every detail

BARTHEL has all the adequate technical facilities on site to prepare each boiler tube perfectly. This includes for example:

- Precise sawing of fixed lengths

- End machining

- Weld seam preparation (chamfering)

The mechanical processing allows the respective product to be perfectly integrated into its environment.

Surface treatment: More than you expect

Do you have special requirements in regard to boiler tubes? If needed, we can take over all necessary ancillary work such as surface treatment in the form of rust protection coating or steel gravel rust removal. We offer customized solutions from simple transport protection coating to top coating. Simply select the required paints and layer thicknesses, we'll take care of everything else.

Whether you are looking for detailed advice or would like to order, we are here for you

Please send your enquiry to barthel_at_buhlmann-group.com

Or call us at: +49 2132 97298 - 50

We will gladly answer your questions or advise you on our products.